These BREAKING News are Brought to you by:

If you are in Construction, Subcontracts, Services, or sell equipment or materials, HERE YOU GO!

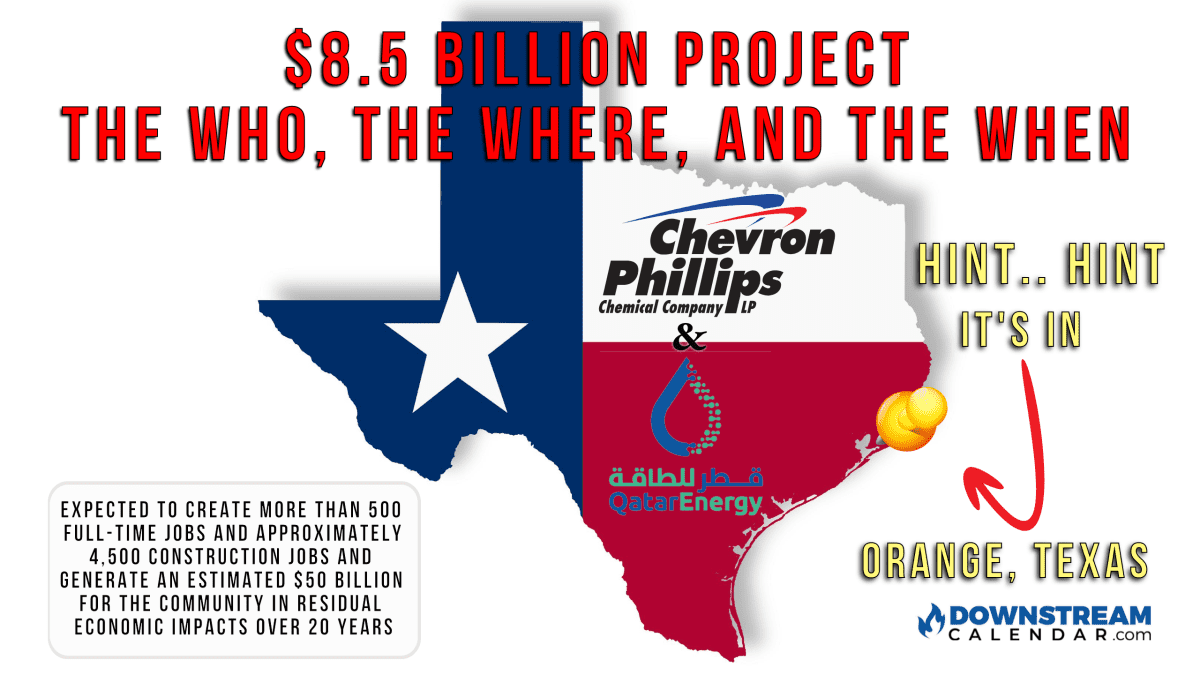

“Chevron Phillips Chemical and QatarEnergy to construct integrated polymers facility on US Gulf Coast

Chevron Phillips Chemical Company LLC and QatarEnergy announced today that they are proceeding with the construction of an $8.5 billion integrated polymers facility in Orange, Texas, expected to create more than 500 full-time jobs and approximately 4,500 construction jobs and generate an estimated $50 billion for the community in residual economic impacts.

The companies have made a positive final investment decision on the project and created a joint venture company, Golden Triangle Polymers Company LLC, named for the Golden Triangle region of Texas that includes the city of Orange. Chevron Phillips Chemical owns a 51% equity share in the joint venture and QatarEnergy owns 49%.

“Chevron Phillips Chemical and QatarEnergy have collaborated for over 20 years on the assets we operate together in Qatar. We have a great relationship and a proven track record of operating these facilities safely and reliably,” said Chevron Phillips Chemical President and CEO Bruce Chinn. “Our products help make life better for billions of people every day, and they are part of a lower carbon future. This facility will help meet the growing demand for our products and improve the quality of life for the world’s growing global population.”

His Excellency Mr. Saad Sherida Al-Kaabi, the Minister of State for Energy Affairs, the President and CEO of QatarEnergy said: “We are excited to announce taking the FID on our largest petrochemical investment ever, highlighting QatarEnergy’s integrated position as a major player in the LNG and international exploration sectors, as well as being a global petrochemicals producer. This important project will complement QatarEnergy’s growing portfolio, both internationally as well as in the United States, and will help meet growing global demand for polymers. It builds on our long-term and successful partnership with Chevron Phillips Chemical, and we look forward to further collaborations in the future.”

Once operational, the plant will produce Marlex® polyethylene. Polyethylene is used in the production of durable goods like pipe for natural gas and water delivery and recreational products such as kayaks and coolers. It is also used in essential packaging applications to protect and preserve food, helping prevent it from going to landfills, and keep medical supplies sterile.

The plant, expected to begin operations in 2026, will include a 2,080 KTA ethane cracker and two 1,000 KTA high-density polyethylene units. The project is targeting to have approximately 25% lower greenhouse gas emissions than similar facilities in the United States and Europe, supporting the company’s efforts to help enable a lower carbon future. Chevron Phillips Chemical will manage engineering, procurement and construction for the project and operate the facility after start-up.

Construction of the Golden Triangle Polymers plant will begin immediately near Chevron Phillips Chemical’s existing facility in Orange, located 113 miles east of Houston. Chevron Phillips Chemical and its predecessors have had a presence in the Orange community since 1955.

The engineering, procurement and construction of the polyethylene units will be executed through ZDJV, a joint venture between Zachry Industrial Inc. (Zachry Group) and DL USA, Inc. The furnace portion of the ethane cracker engineering and procurement will be executed by T.EN Stone & Weber Process Technology, Inc. while PCL Industrial Construction Co. will provide construction services. Engineering, procurement and construction for the additional portions of the ethane cracker will be executed by JKJV, a joint venture between JGC America, Inc. and Kiewit Energy Group, Inc., and BMZ Third Coast Partners, a joint venture between Burns & McDonnell Engineering Company, Inc. and Zachry Industrial, Inc., (Zachry Group) will execute the utilities and infrastructure scope of work. The main automation contractor for the project is Emerson Process Management, LLLP, and W.T. Byler Co., Inc. is managing heavy civil work for the entire site. The project also includes a rail and storage-in-transit yard, with engineering, procurement and construction services provided by W.T. Byler Co., Inc.

“We work hard to be a good neighbor in the communities where we operate, and we are extremely grateful to the community members and public officials in Orange for their support as we developed this project,” Chinn said. “This facility will contribute to the social and economic fabric of the entire Golden Triangle region of Texas, bringing in thousands of high-paying American jobs and billions of dollars in economic impact. We care deeply about the community of Orange, and we’re thrilled to be bringing jobs and resources to the region with safety and environmental performance at the forefront, as always.”

For more information about the project and to contact us, visit www.cpchem.com/goldentrianglepolymers. ”

“CPChem and QatarEnergy have announced plans to construct an $8.5 billion integrated polymers facility in Orange, Texas. The companies created a joint venture company, Golden Triangle Polymers Company LLC, named for Texas’s Golden Triangle region that encompasses the community of Orange.

The new facility is expected to create more than 500 full-time jobs and approximately 4,500 construction jobs and generate an estimated $50 billion for the community in residual economic impacts over 20 years.

Once operational, the plant will produce Marlex® polyethylene. Polyethylene is used in the production of durable goods like pipe for natural gas and water delivery and recreational products such as kayaks and coolers. It is also used in essential packaging applications to protect and preserve food, helping prevent it from going to landfills, and keep medical supplies sterile.

The plant, expected to begin operations in 2026, will include a 2,080 KTA ethane cracker and two 1,000 KTA high-density polyethylene units. CPChem will manage engineering, procurement and construction for the project and operate the facility after start-up.”